So after multiple attempts removing and refitting the carburettors for road tuning I've found a pretty spot on tune. The engine is smooth throughout the entire rev range while maintaining the top speed and regaining the torque it lost from the rich jetting.

Main jets: 112, 110, 110, 112

Pilot screws: 2-1/8 turns

Stock airbox and filter with the restrictor plate removed, running the standard bellmouths (short, tall, tall, short).

Thanks to Sam Moore for his advice on jetting and tuning.

Monday, 20 November 2017

Thursday, 12 October 2017

666 Runs

After almost a year sitting in a garage the MC22 has finally had its dignity restored.

Handling has improved by a mile in comparison to what it used to be thanks to the front suspension and weight changes. The higher rearset positioning provides a more aggressive body position over the bike which is far more enjoyable for cornering (not to mention eliminating peg scrape), and when coupled with the weight loss from the fibreglass fairings, exhaust and other small reductions it really does feel stupidly nimble.

In terms of engine performance it's running rich with the 115/118 size jets and the pilot mixture screws do need further adjusting. The exhaust constantly pops at midrange rpm and blows flames at higher rpm, which is likely unburned fuel just being dumped into the exhaust and igniting. Whether or not the full titanium system is contributing to that is another story but it's definitely down on torque.

The 14-53 gearing suits tight sections of road and small circuits as expected. To compare with stock gearing- 6th gear at 100km/h is 9,000rpm, which is now instead 80km/h and the top speed has reduced to 161km/h on limiter. Somewhere in the middle, say 47T or slightly smaller would be a good future rear sprocket replacement; but for now it's great fun in tight twisties.

The style of the bike was heavily influenced by the バイク 走り屋 era- a period during the 80's/90's that involved teams of young motorcycle enthusiasts who would race on public roads in Japan.

Below is a list of aftermarket parts used in the build:

DOMINO Road Racing Grips

ECLIPTECH LED Brake Light

EK CHAINS 520SRX2 Chain

FANATIC Short Type Bar Ends

HEL Braided Brake Lines

HRC Rear Reservoir Delete Kit

KKK PRODUCT Preload Adjusters

KN PLANNING Switch Kit

KOSO RX2N & LCD Multimeter

KOSO Super Slim Style Voltmeter

METALGEAR 53T 520 Rear Sprocket

METALGEAR Front Brake Rotors

MOTOGEAR 4-1 Type Prism Full Titanium Exhaust System

N PROJECT Wide View Assist Mirrors

POSH Aero Sharp Mini Blinkers

SILHOUETTE JAPAN Cowl

SSB POWERSPORT Lithium Battery

SUNSTAR 14T 520 Front Sprocket

TYGA PERFORMANCE 30mm Mirror Blanking Plates

TYGA PERFORMANCE Front Fender

TYGA PERFORMANCE Rear Stand Hooks

XCITEBIKES Adjustable Levers

*All other parts are either unbranded, custom or OEM.

Sunday, 1 October 2017

Switchgear and Thermo Fan Manual Switch

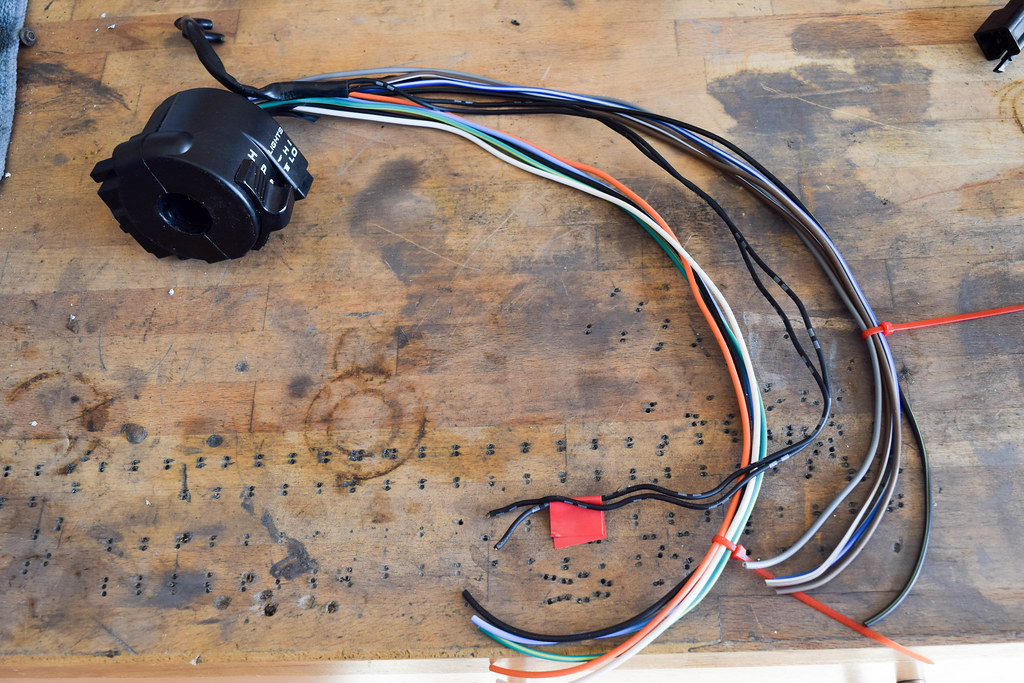

Grey import switch gear for these bikes don't exist as new stock anymore and second hand units are usually in poor condition. I used a generic 5/8" switch gear from Ebay as an alternative which is cheap and works perfectly. The manufacturer from china has basically just reverse engineered a honda switch gear so all the internals are wired the same, just different plugs and colour wiring. All that was needed to do was transfer the clutch switch wiring, oem plugs and match up the wires to their functions.

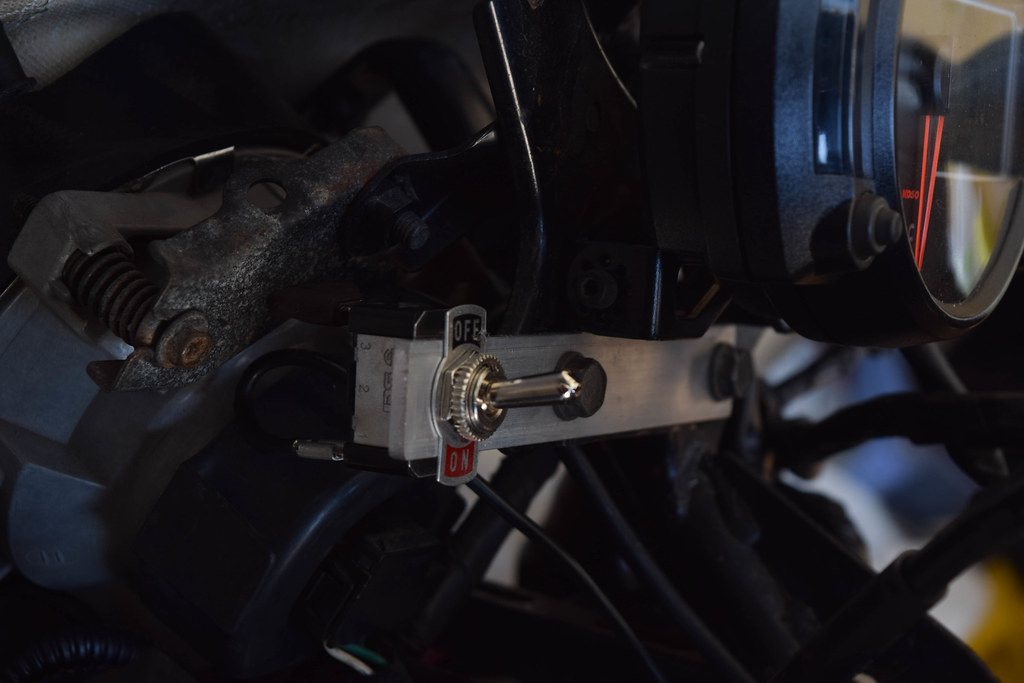

Another electrical change was to the thermo temperature switch. A common fault on these bikes is the temperature switch that sits on the bottom left of the radiator fails and ultimately stops the thermo fan from ever turning on- no longer cooling the bike while stopped or at low speed. Installing a manual switch is definitely one of the easiest modifications that can be done on these bikes.

A new bracket for the KOSO dash was made up which has space for a SPST 2 position switch.

The wire connected to the temperature switch on the radiator was unplugged and runs over the top of the bottom triple, connecting to the 'off' side of the switch. From there a new wire runs from the 'on' side of the switch to one of the fairing stay bolts, earthing it on the frame of the bike.

|

| New Ebay switch gear - Straight out of the box |

|

| Loom for the switch gear organised and ready for the plugs to be soldered |

|

| Switch gear all soldered and taped, ready to go on the bike |

|

| Switch gear installed |

A new bracket for the KOSO dash was made up which has space for a SPST 2 position switch.

|

| Manual switch insalled |

|

| Switch complete |

Monday, 25 September 2017

Fairings Painted

Thanks to K&F Customs Panel & Paint for their hard work repairing all the small fibreglass imperfections and working their magic with the paint. The colour choice was Mazda Brilliant Black with a layer of silver flake over the top. POSH Aero Sharp indicators and N PROJECT mirrors were installed at the same time too.

Full fairing kit on/off:

Full fairing kit on/off:

Friday, 15 September 2017

General Servicing

With everything else on the bike sorted the remaining running gear needed to be serviced. This included the battery, spark plugs, brakes, brake lines, brake fluid, rear brake reservoir, coolant, engine oil and oil filter. Other things that will need to be addressed in future are tyres and front brake pads.

The original battery dropped a cell on the first attempt to turn the engine over so a replacement was needed. Lithium batteries are surprisingly cheap now and weigh about 1/3 of a normal liquid battery, making the SSB Powersport Lithium battery a great replacement. I also replaced the spark plugs with NGK Iridium CR9EHIX-9 spark plugs which are less prone to fouling.

HEL braided lines were fitted including a HRC rear brake reservior kit before both systems were filled and bled.

To start, the engine was serviced with full synthetic Penrite 10w-40 oil and a Hiflofiltro HP111 oil filter.

In order to clean the coolant system a 50/50 mix of cleaning vinegar/water was ran at operating temperature, then a second time with just water to flush the system before finally being filled with Toyota Red coolant. A new coolant overflow bottle was made up too, mounted from a bracket behind the radiator to replace the original overflow tank that usually sits behind the engine.

In order to clean the coolant system a 50/50 mix of cleaning vinegar/water was ran at operating temperature, then a second time with just water to flush the system before finally being filled with Toyota Red coolant. A new coolant overflow bottle was made up too, mounted from a bracket behind the radiator to replace the original overflow tank that usually sits behind the engine.

The original battery dropped a cell on the first attempt to turn the engine over so a replacement was needed. Lithium batteries are surprisingly cheap now and weigh about 1/3 of a normal liquid battery, making the SSB Powersport Lithium battery a great replacement. I also replaced the spark plugs with NGK Iridium CR9EHIX-9 spark plugs which are less prone to fouling.

HEL braided lines were fitted including a HRC rear brake reservior kit before both systems were filled and bled.

Wednesday, 6 September 2017

Valve Clearance Check

After all the effort put into getting things perfect on this bike, it was always going to be impossible to have peace of mind without making sure the valve clearances were within spec; even if the adjustment on the previous engine came to unfortunate outcome due to my mistake. Thankfully the clearances had been done fairly recently on this motor as they were all within spec and the cams, holders and shims could all stay where they were.

For reference, these were the measurements:

CYLINDER 1:

Exhaust (1, 2): 0.229, 0.229

Intake (3, 4): 0.178, 0.152

CYLINDER 2:

Exhaust (1, 2): 0.203, 0.203

Intake (3, 4): 0.178, 0.178

CYLINDER 3:

Exhaust (1, 2): 0.229, 0.229

Intake (3, 4): 0.178, 0.178

CYLINDER 4:

Exhaust (1, 2): 0.203, 0.229

Intake (3, 4): 0.178, 0.178

ACCEPTABLE TOLERANCE:

Exhaust: 0.200 - 0.260

Intake: 0.130 - 0.190

For reference, these were the measurements:

CYLINDER 1:

Exhaust (1, 2): 0.229, 0.229

Intake (3, 4): 0.178, 0.152

CYLINDER 2:

Exhaust (1, 2): 0.203, 0.203

Intake (3, 4): 0.178, 0.178

CYLINDER 3:

Exhaust (1, 2): 0.229, 0.229

Intake (3, 4): 0.178, 0.178

CYLINDER 4:

Exhaust (1, 2): 0.203, 0.229

Intake (3, 4): 0.178, 0.178

ACCEPTABLE TOLERANCE:

Exhaust: 0.200 - 0.260

Intake: 0.130 - 0.190

Friday, 1 September 2017

Rearset Modification

The stock rearsets can become problematic when it comes to full lean clearance and while they do pivot to adjust for this, personally the idea of scraping the pegs doesn't sound like a good time. Originally I planned to go aftermarket but decided instead to use brackets to replicate a similar footpeg position that aftermarket rearsets provide. Cardboard was used to make templates first before being transferred to the aluminum flatbar and cut out to fit. The final result are stock rearsets that now sit 50mm higher and 30mm further back.

Wednesday, 23 August 2017

14/53T 520 Pitch Sprocket Conversion

The stock gearing of the MC22 consists of a 17 teeth front sprocket, 52 rear sprocket and a 428 pitch chain. The existing sprockets were far too worn to use again and after looking at alternatives a 520 pitch conversion seemed a viable choice with lots of sprocket options. I decided to go with a 14 tooth front sprocket paired with a 53 tooth rear and change it in future if it's too ridiculous, this combination provides quicker acceleration while sacrificing top speed.

The front sprocket is a SUNSTAR 14 tooth paired with a METALGEAR 53 tooth rear sprocket and QX-RING 520SRX2 chain.

|

| New 520 pitch 14 tooth sprocket on the left, Original 428 pitch 17 tooth sprocket on the right |

|

| Original 428 pitch 54 tooth sprocket on the left, New 520 pitch 53 sprocket on the right |

Thursday, 10 August 2017

Fairing Kit Completed

The last pieces of the fairings arrived and the bike could finally get a glimpse at being complete again with a new front cowl, windscreen and front fender. The front cowl is a late 90's endurance FRP cowl, made by SILHOUETTE JAPAN. Very rare to come by in good condition as they are discontinued and can only be found second hand at japanese auctions. An OEM windscreen is to go with the cowl and for the front fender I opted for a cheap FRP TYGA unit as the stock one didn't suit at all.

|

| SILHOUETTE JAPAN front cowl |

|

| SILHOUETTE JAPAN front cowl and TYGA front fender fitted |

|

| OEM Windscreen |

Tuesday, 8 August 2017

Replacement Engine

After having issues starting the bike and trouble shooting for about a week, it turns out the engine has really sad compression readings. Double checking the carbureter settings, valves clearances and camshaft positions wasn't a fun time, then I found the ignition leads were badly corroded and replaced those with a spare set (a positive in hindsight) but it was a leak down test that revealed there was more than 80% leakage through the intake valves, which suggests something along the lines of bent valves. Considering it was running (albiet roughly) a year ago I would put it down to my own error at some stage while doing the clearances and not prior damage from the crash. One thing that does come to mind was that the torque wrench used was 1/2 inch and exceeding it's accurate range for the low torque settings on the cam holders.

Head rebuilding for an MC22 engine is more complicated than larger motorcycle engines and fairly costly when compared to buying a second hand engine. Thankfully sourcing a second hand motor wasn't too difficult, picked it up one afternoon and had it in the frame within an hour. These motors are bulletproof and will happily run past the point where the odometer resets but they need a lot of care when touching internals, something that will definitely be kept in mind when it's time to do the valve clearances on this second motor.

Huge thanks to Riley Duddles for providing a second hand engine and Rob Fry for lending his time, knowledge and workshop for a leak down test on the original engine.

Head rebuilding for an MC22 engine is more complicated than larger motorcycle engines and fairly costly when compared to buying a second hand engine. Thankfully sourcing a second hand motor wasn't too difficult, picked it up one afternoon and had it in the frame within an hour. These motors are bulletproof and will happily run past the point where the odometer resets but they need a lot of care when touching internals, something that will definitely be kept in mind when it's time to do the valve clearances on this second motor.

Huge thanks to Riley Duddles for providing a second hand engine and Rob Fry for lending his time, knowledge and workshop for a leak down test on the original engine.

Friday, 28 July 2017

KOSO RX2N+ Meter Installation

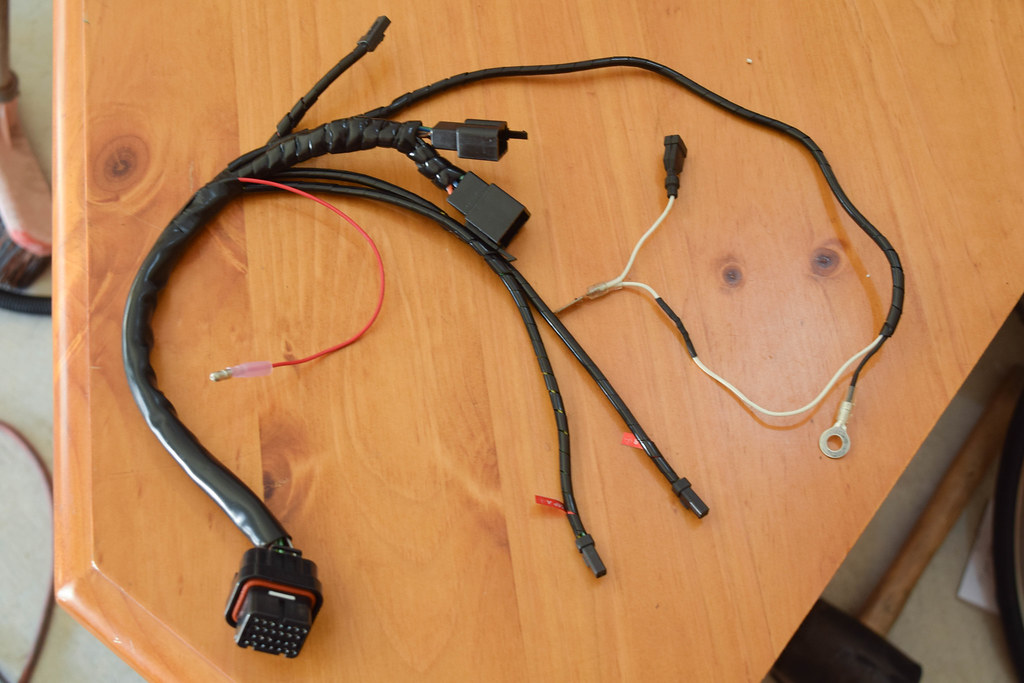

The KOSO RX2N+ is a digital race meter and while it does look great it's the functional advantages that make it a worthy replacement over the OEM MC22 dash. It's most useful features in this case are the two temperature displays, magnetic speedometer pickup, shift light, 24 hour clock and warnings like high temperature/high speed readings. Using it allows for the correct speed to be shown with the new sprockets as the magnetic speedo pickup will run off the front wheel rather than a drive off the front sprocket.

In regards to installation it was fairly straight forward, the main harness needs to be wired into the existing MC22 loom with a new positive wire straight from the battery as main power to the meter, the magnetic speedo pickup needs to be mounted off the front forks and the temperature/speed sensors are direct plug and play. There are two issues to highlight though, the first being that the CDI thinks the speed limiter is active when you replace the dash and restricts the engine to 8,000RPM; this was fixed by shorting two wires from the CDI. The second is that using the MC22's RPM signal wire causes reading issues at low RPM due to EMI in the loom, so routing a shielded wire from one of the coil packs was necessary.

Cutting the KOSO bracket down and drilling a new hole for the thread on the MC22's fairing stay provided the top clearance for the windscreen. From there a second bracket was made from aluminium flatbar allowing it to be securely fixed without any modification to the fairing stay.

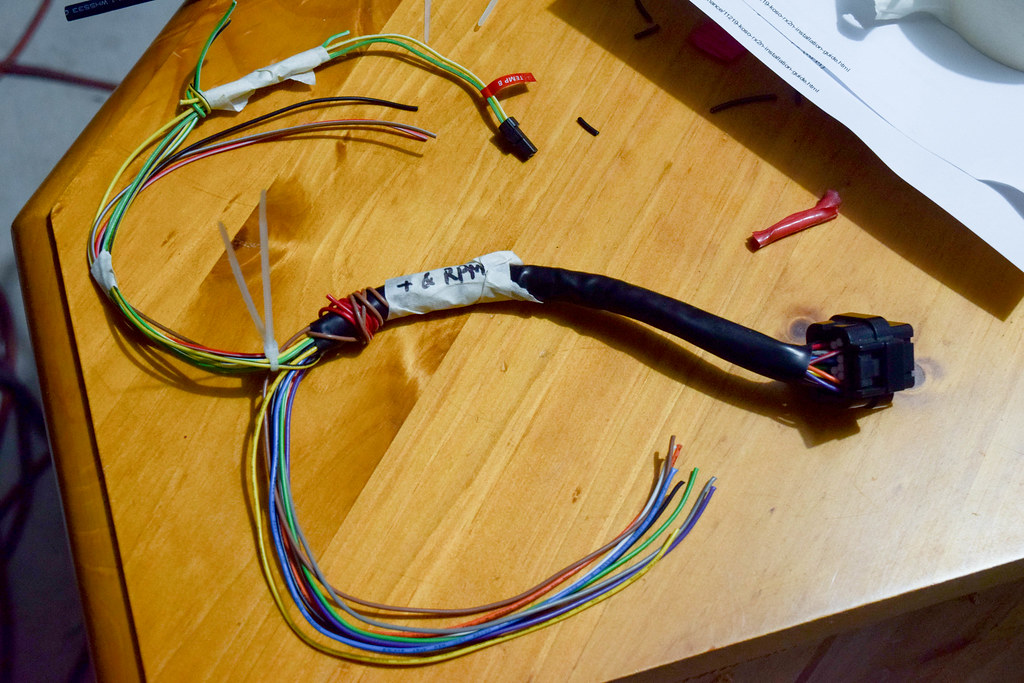

The next stage is wiring the KOSO's harness into the MC22's wiring loom and the easiest way to do that is to cut the connectors off the old MC22 dash and wire those to the KOSO harness; keeping it neat and plug & play. The harness is much longer than needed so trimming that down and mocking up the wire routing was the first priority.

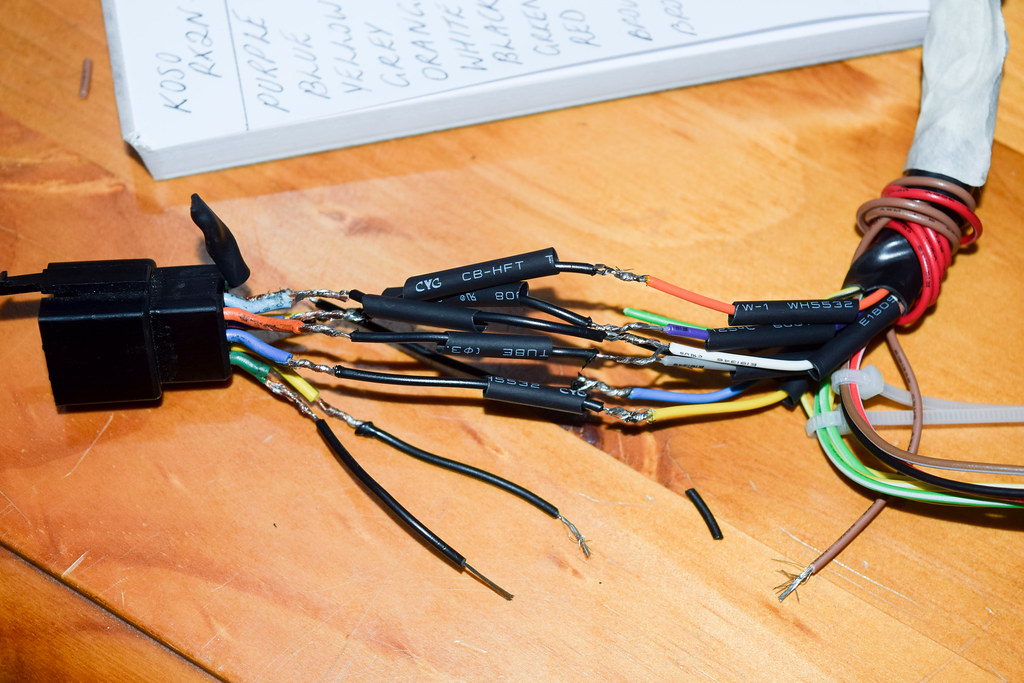

Soldering the wiring together and heat shrinking is always the best option, rather than using the crimp on connections included in the kit.

The wiring connections are listed below along with their purpose.

KOSO -> MC22

Black -> Green ☆ Purpose: Earth

Blue -> Light Green w/ Red Stripe ☆ Purpose: Neutral Light

Brown (With Connector) -> +Side Ignition Coil Pack ☆ Purpose: RPM Signal

Brown -> Brown ☆ Purpose: 12V Ignition (Key on)

Green -> N/A ☆ Purpose: Fuel Signal

Grey -> Orange ☆ Purpose: Left Turn Signal

Orange -> Dark Blue w/ Red Stripe ☆ Purpose: Oil Pressure Light

Red -> 12V+ Battery ☆ Purpose: 12V Main Power (Constant)

Violet -> Black/Yellow ☆ Purpose: EOBD Light (Side Stand Indicator)

White -> Light Blue ☆ Purpose: Right Turn Signal

Yellow -> Blue ☆ Purpose: High Beam Light

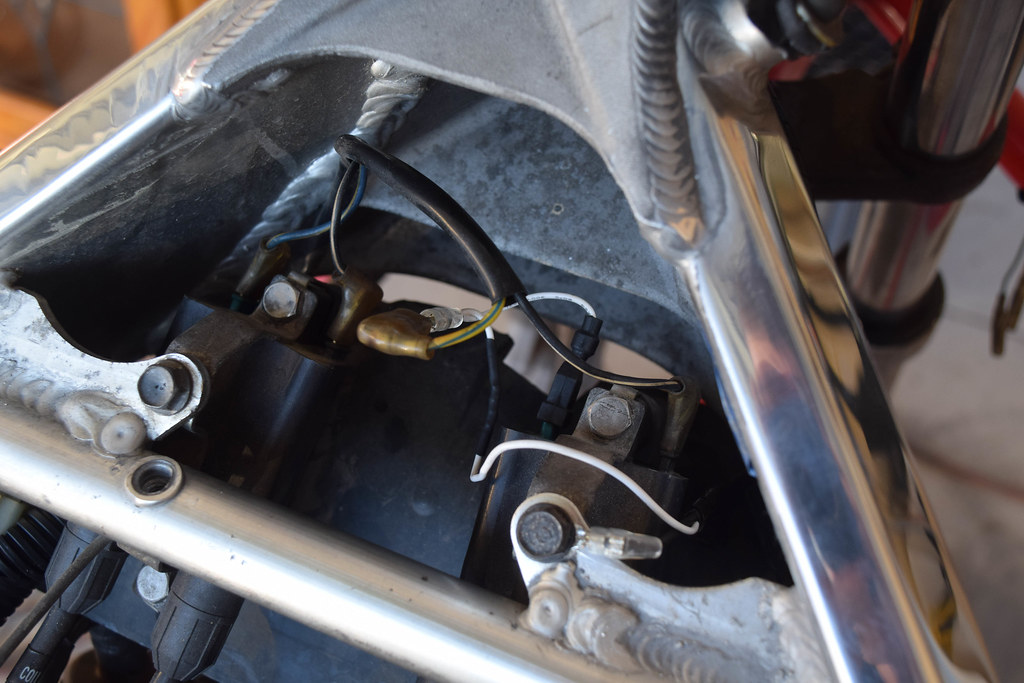

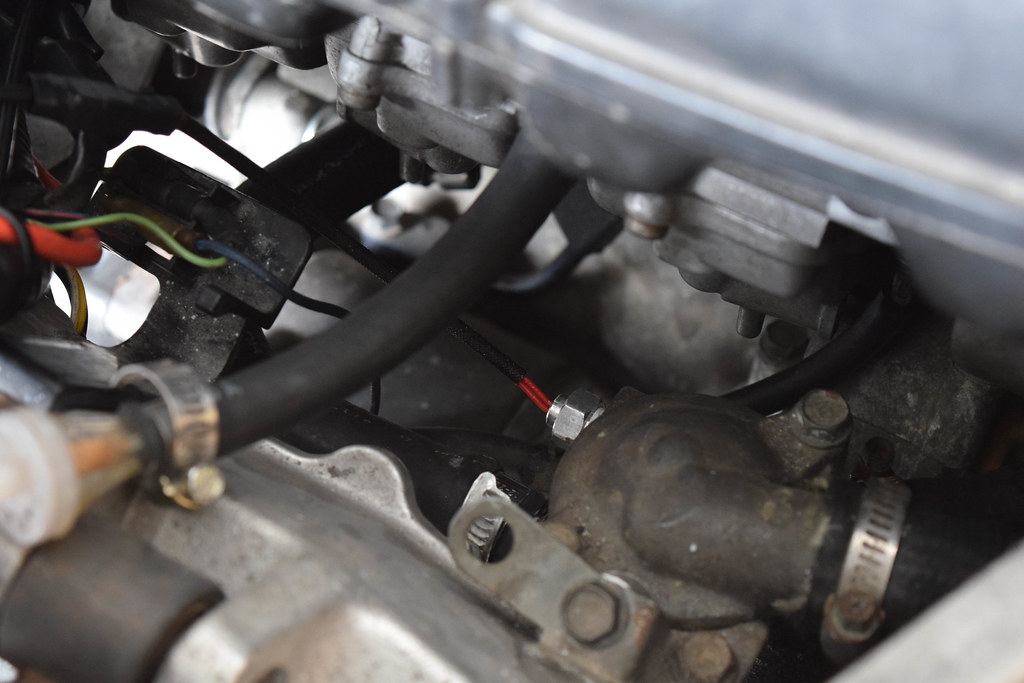

One of the two temperature sensors simply replaces the existing factory sensor on the thermostat behind the carburetors.

The last step of the installation before powering on the unit and configuring the settings was to cut the Orange/Blue wire from the CDI and splice it into the Black/White wire. This deactivates the speed limiter.

As a reference point for settings, 2 sensor points and 1810mm for the wheel circumference in the speed sensor setting and HiAct and 1 (4C-2P) in the RPM input pulse setting.

In regards to installation it was fairly straight forward, the main harness needs to be wired into the existing MC22 loom with a new positive wire straight from the battery as main power to the meter, the magnetic speedo pickup needs to be mounted off the front forks and the temperature/speed sensors are direct plug and play. There are two issues to highlight though, the first being that the CDI thinks the speed limiter is active when you replace the dash and restricts the engine to 8,000RPM; this was fixed by shorting two wires from the CDI. The second is that using the MC22's RPM signal wire causes reading issues at low RPM due to EMI in the loom, so routing a shielded wire from one of the coil packs was necessary.

☆PROCESS☆

The first step is mounting the KOSO unit itself to the MC22's fairing stay. It will mount up fine using the bracket provided with an extra bolt/washer but due to clearance with the new cowl and windscreen it needed to be modified.

.

.

Cutting the KOSO bracket down and drilling a new hole for the thread on the MC22's fairing stay provided the top clearance for the windscreen. From there a second bracket was made from aluminium flatbar allowing it to be securely fixed without any modification to the fairing stay.

The next stage is wiring the KOSO's harness into the MC22's wiring loom and the easiest way to do that is to cut the connectors off the old MC22 dash and wire those to the KOSO harness; keeping it neat and plug & play. The harness is much longer than needed so trimming that down and mocking up the wire routing was the first priority.

Soldering the wiring together and heat shrinking is always the best option, rather than using the crimp on connections included in the kit.

The wiring connections are listed below along with their purpose.

KOSO -> MC22

Black -> Green ☆ Purpose: Earth

Blue -> Light Green w/ Red Stripe ☆ Purpose: Neutral Light

Brown (With Connector) -> +Side Ignition Coil Pack ☆ Purpose: RPM Signal

Brown -> Brown ☆ Purpose: 12V Ignition (Key on)

Green -> N/A ☆ Purpose: Fuel Signal

Grey -> Orange ☆ Purpose: Left Turn Signal

Orange -> Dark Blue w/ Red Stripe ☆ Purpose: Oil Pressure Light

Red -> 12V+ Battery ☆ Purpose: 12V Main Power (Constant)

Violet -> Black/Yellow ☆ Purpose: EOBD Light (Side Stand Indicator)

White -> Light Blue ☆ Purpose: Right Turn Signal

Yellow -> Blue ☆ Purpose: High Beam Light

The last two wires left were the RPM signal and direct 12v feed, for the direct 12v a bullet style connector was used and the RPM signal wire was modified from the shielded cable provided in the kit.

To help eliminate any possible EMI the RPM signal wire runs along the front fairing stay, through the front triple and under the frame to the right side ignition coil.

One of the two temperature sensors simply replaces the existing factory sensor on the thermostat behind the carburetors.

The MC22 doesn't come factory with any engine temperature sensor or fitting for one apart from the oil pressure sensor, but that's far more important than knowing the temperature of the oil. Two options came to mind, either drill and tap the sump or use an adapter where the sump drain plug sits. Due to not having a tap and die set at my disposal I chose the latter, and with a M14X1.5 to 1/8NPT adapter the sensor can be mounted from the sump. The downside is that it will make future oil changes less convenient.

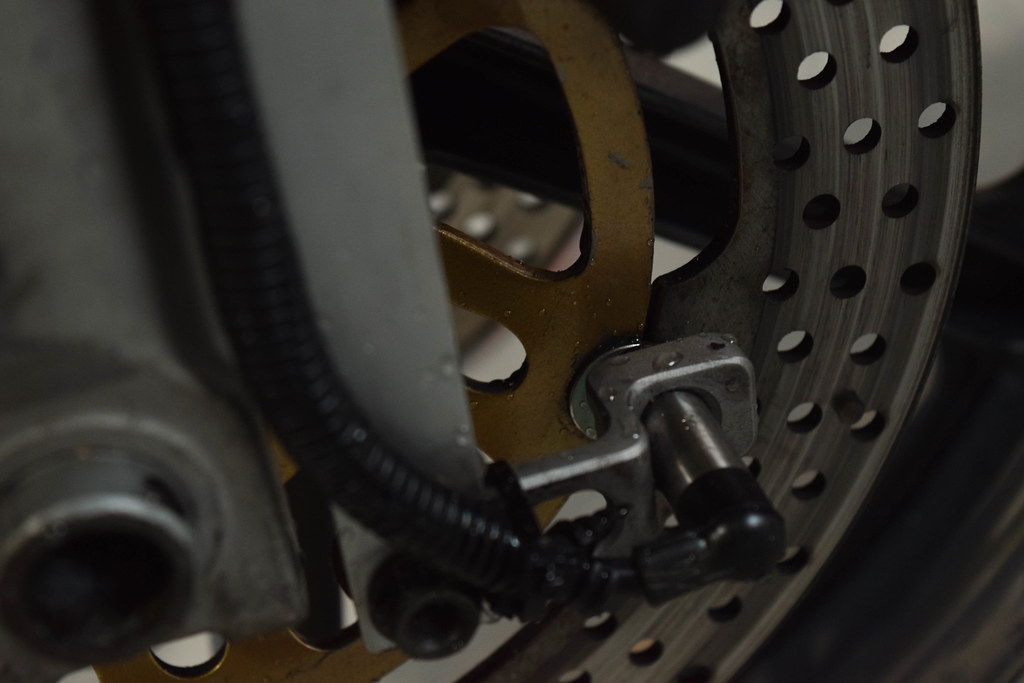

The magnetic speedometer pickup works by sensing points on the brake rotor and calculating the speed based off the rate in which they pass the sensor. After trial and error the best result was to use the buttons on the brake disc and original MC22 fairing bolts with lock nuts, two spaced opposite from eachother. More sensor points on the brake rotor mean a more fluid reading but it also throws the balance of the wheel off if too many are added.

To mount the sensor a bracket cut from aluminium flatbar was made to fit infront of the left side caliper.

The sensor needs to be within 2mm or less from the sensor point to get the best performance.

The last step of the installation before powering on the unit and configuring the settings was to cut the Orange/Blue wire from the CDI and splice it into the Black/White wire. This deactivates the speed limiter.

As a reference point for settings, 2 sensor points and 1810mm for the wheel circumference in the speed sensor setting and HiAct and 1 (4C-2P) in the RPM input pulse setting.

Subscribe to:

Comments (Atom)